Research

Research

Finding the right type of steel that will stand up to the stress due to fall-arrest and not create a hazard is a must, that is why we at CCL spent a lot of time researching and testing steel types and coatings before we started manufacturing height safety anchor points. The purpose of having any height safety anchor points on a building is to minimise the risk of a fall. Research and testing has showed us that by using tensile steel you can create a hazard and place the user at risk.

After searching the web I came across Hooks Law and Young`s Modulus, this covered what I was looking for. Hooks Law explains about the elasticity of steel when loads are applied. Hooks Law / Young`s Modulus

Rule of thumb

When designing any height safety anchor points that bend to reduce loading the anchor should be manufactured from steel that has elastic properties. By using steel that has tensile properties such as 316 or 304 Stainless Steel the anchor can change from elastic to plastic in a heart beat and snap without warning making the anchor unsafe for the user. NB: This principle is used by Structural Engineers when designing building structures

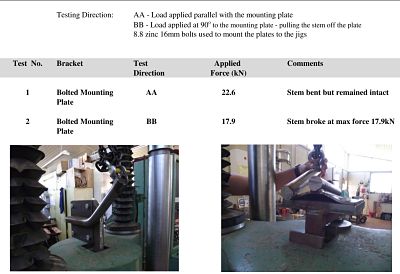

Testing

We engaged the services of a QSI Testing during the design process to ensure that our features were optimized. We Static load tested different types of steel to note the effects. Because we were static testing, we tested the anchors to 15kN stop the test, release the load and reloaded the anchor to breaking / yield. This testing showed the strength in mild steel as a height safety anchor point, and the weakness in tensile steel for the same application. Some of our design features can be seen in the standards today.

NB: When a person falls the anchor comes under strain throughout the fall, once at the bottom of the fall the load decreases and a secondary load is applied, it is at this point the anchor could snap and fail. Our testing has proved this time and again when we have tested using any steel with tensile properties.

Types of steel tested

- Mild Steel 30mm Black Bar 300 grade

- Mild Steel 10mm Black Bar 300 grade

- Mild Steel 6mm Light Plate 250 grade

- Mild steel with Galvanized coating

- Mild steel with Zinc coating

- Tensile steel 4.4 and 8.8

- Construction Quality Bar better known as CQ

Elasticity & Shock Loading

Mild Steel has the ability to maintain it`s elasticity after being bent a number of times until it reaches it`s maxim yield and this makes it safe as an anchorage point for Fall-Arrest or Abseil.

All height safety anchor points have to sustain shock loading when a fall occurs, we feel that use of any stainless steel is not suitable for anchor points because they can become brittle due to stress or cold temperature and snap without warning. Growing up around yachts in NZ there is a term that is used most common and that is gear failure, you hear it most commonly used when 316 or 304 stainless steel fittings on yachts break due to stress. If you go into any boat shop anywhere around the world you will aways find replacement 316 or 304 stainless fittings in stock on the shelves. Many things can cause 316 or 304 stainless steel fittings to break but the biggest thing is stress loading or cold temperatures.

Mild Steel

Is a low grade mild steel and has been used because it is not brittle, this grade of steel bends gradually as loads are imposed on the Anchor. We noted during the testing process that tensile steel had a tendency to fracture and snap at lower loading capacities. Mild steel offers more elasticity than tensile steel under loading. When a secondary loading has been applied all tensile steel tested snapped with out warning.

Mild steel is the most commonly used ferrous metal.. It contains about 0.15 to 0.30% carbon and the rest is iron. As mild steel has a low carbon content, it cannot be hardened and tempered; however, it is malleable and ductile, and bends easily. It is used in the manufacture of nuts, screws, bolts, girders and other general metal products.

Tensile Steel

Tensile Steel has limited elastic properties, when tensile steel is stressed up to it`s elastic limit it then changes from elastic to plastic, this makes the steel much more brittle and the steel can snap without warning. This can be a hazard to the user. Our research also showed, the use of tensile steel in cold temperatures can cause the steel to snap at a lower yield without warning.

NB Tensile steel should only be used in shear loading and not stress loading.

Bending

Bending of the anchor due to significant loading is a safety feature that will alert any prospective user that the Anchor has been damaged and should be replaced before anybody attempts to use it. Bending may occur if the Anchor is used for some purpose other than fall prevention or fall arrest. It is amazing what Anchors have been used for in some situations.

Manufacturing

- All products are manufactured to a high standard

- Safetor products are manufactured using mild steel

- Will deform gradually when loads are imposed on them

- Have ease of adjustment for installation to different size structural members

- Provide for immediate visual signs of having had a load imposed on them

Collins Corporation believes that these features are very important aspects for consideration when choosing which type of Anchor Device to install in any building or structure.

We still engage the services of a Telarc registered Material Testing Laboratory to ensure that compliance continues with the Australian and New Zealand Standards.

Powdercoating

Plascoat PPA 571 ES is resistant to stress cracking, adverse weather conditions, detergents, salt spray and typical airborne pollutants. The coating maintains excellent adhesion to the metal substrate without the need for a separate primer. The material also provides good abrasion and impact resistance.

WHY NOT GALVANIZING?

We tested our product with galvanizing as the protective system. The results were alarming. The load bearing capacity was reduced to less than half of that for the zinc plated product. The galvanizing process alters the tensile properties of steel, which in our case causes a fracturing and breaking of the Anchor stem at a load less than we were happy with as a safety margin.

Galvanizing does not provide the durability protection required in the Building Code for coastal and harsh environs.

IS STAINLESS STEEL an option?

Yes but only in some cases. We have investigated the use of grade 316 stainless steel and found that the load bearing capacity is lower for the same dimension components in most cases.

- Tensile steel works best in shear so stemmed anchors are not an option:

- Low temperatures around -10 can cause tensile steel to react differently.

- The product would be more costly to produce (almost three times) and in most cases would provide very little added value to the building owner.

- Be aware that there can be a reaction between stainless steel and some roofing product materials causing corrosion of the roofing material and the stainless steel.

If stainless steel is an absolute necessity, and we are able to supply Anchors in grade 316.