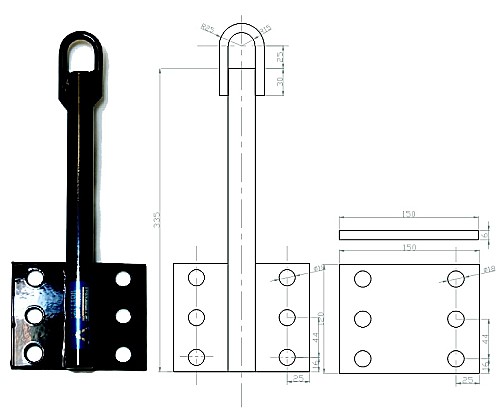

S/E 015 High Profile Anchor

All exposed Safetor Roof Anchors meet the requirements of the AS 5532:2025 Anchor testing Standards; AS/NZS 1891.2:2001 Horizontal Lifeline and Rail Systems Standards; AS/NZS1891.4:2025 Industrial Fall Arrest Systems and Devices Standards. This is our most popular anchor.

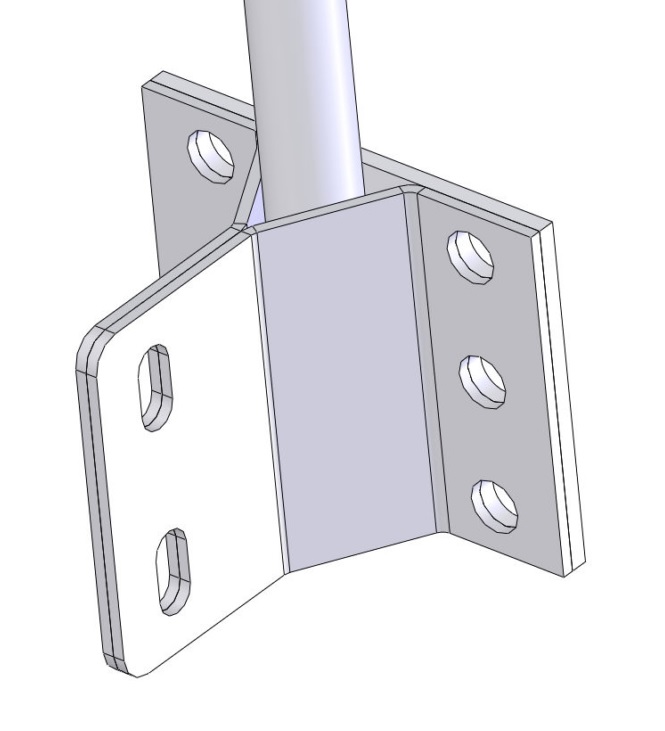

Design

The S/E 015HP anchor is designed to be bolted to 4 x 2 timber trusses, timber purlins or steel purlins. This High Profile anchor can be used for Fall-Arrest, Abseil and as an end anchor for lifelines. Manufactured from a 30mm Mild Steel solid bar with an overall height of 335mm. The mounting plate is 4mm thick Mild Steel with 3 x 16mm holes on either side of the main shaft. This anchor comes with a backing plate which matches the mounting plate.

Load reduction

The Safetor S/E015 anchor can reduce the loading on the structure to 3.8kN

Certification

The S/E 015HP has three certifications

- Testing by Material & Testing Laboratories

- Chartered Professional Engineer Certificate Number 66313

- QSI Testing Laboratories

Applications as per AS/NZS 1891.4:2025, & AS 5532:2025 Standards: Strength Requirements and Testing for Anchorages

Ultimate Strength

- End anchor for horizontal line – 44kN

- Limited free-fall arrest for one person: 12kN

- Free-fall arrest for one person: 15kN

- Limited free-fall arrest for two people: 18kN

- Free-fall arrest for two people: 21kN Anchors can also be classified as either fixed or temporary.

NB:

- Anchorage strength applicable when using a restraint technique, is either 15kN or 12kN depending on whether the ultimate fall is free-fall or limited free-fall.

- ‘Ultimate strength’ means that the anchorage may yield at the stated load but must not fail.

Anchor Material:

- Mild Steel 30mm Black Bar 300 grade

- Mild Steel 10mm Black Bar 300 grade

- Mild Steel 6mm Light Plate 250 grade

Bolts

Bolts used to attach the anchors are M16mm Construction Bolts. The number of bolts used to attached the anchor to the structure can be 2 to 4 sets of bolts. All the timber testing to date on 4 x 2 framing has been using 2 x sets of bolts.

NB:

The only time we recommend the use of 4 bolts is when the anchors are attached to C-Section light gauge steel purlins.

Safetor Roof Anchor Bracing System

The S/E 015 has a two piece bracing plate which is attached using the mounting plate bolts. This plate allows for bracing to be bolted between the anchor and a bracket on the purlin below for a more solid connection. (see details)

NB:

As there are a number of different sizes of purlins we do not supply the galvanized purlin brackets which can be obtained from the purlin manufacturer.

Welding

All welding has been carried out by engineers that are certified to ASME IX Standards.

Blasting

Profile blasted to remove all scale and grease etc.

Safetor Height Safety Anchors

Are protected with a robust Thermoplastic Powder Coating which must be inspected before and after use for any surface scratches that has damaged the coating system. It is most important that these scratches are addressed straight away. It is very simple, all you need to do is use a heat gun to fuse the Thermoplastic Powder Coating back together to remove the scratch altogether. It is very easy to protect the anchor coating with the use of masking tape or a thin piece of rubber before inserting the carabiner.Coatings

Plascoat PPA 571 ES is resistant to stress cracking, adverse weather conditions, detergents, salt spray and typical airborne pollutants. The coating maintains excellent adhesion to the metal substrate without the need for a separate primer. The material also provides good abrasion and impact resistance.

Membrane Flashing

Installation

The installation should only be carried out by a competent person as set out in the AS/NZS 1891.4:2025 Standards. It is the responsibility of the installer to supply to the building owner clear instructions as per the AS/NZS1891.2.2001 section 5.3. Installed systems A & B, as well as a maintenance program for the care of their height safety anchor points. It is the responsibility of the installer, building designer or building owner to ensure that the structure which the Safetor Roof Anchor is attached to will support a load of at least 15kN as set out in the AS/NZS 1891.4:2025 Standards. If there is any doubt about the structures adequacy, a structural engineer should be consulted.