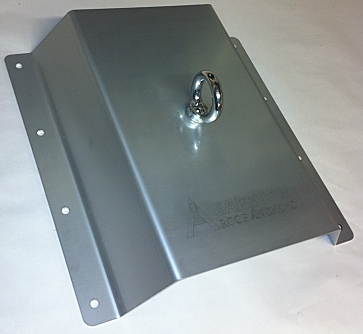

TRHP High Profile Tray & Anchor

Design

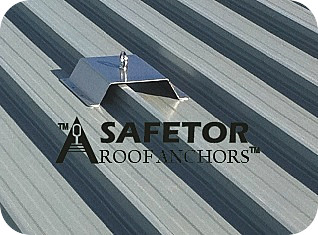

The Safetor Tray and High Profile Roof Surface Anchor or (TRHP) is manufactured from Stainless Steel and is riveted and bonded to Tray Section or High Profile Roofing.

We recommend using all three methods of fixing systems:

- Bonded using Sikaflex 11FC NB: Read all Product Data Sheets before using Sikaflex 11fc

- Riveted using 6 x 7.70 Olympic Bulb-Tite rivets complete with EPDM washer

- 2 x roof tek screws

Rated for: Fall Arrest – Abseil – Restraint

Ultimate Strength:

- 1 person – Free Fall Arrest – 15kN

- 1 person – Abseil -12kN

System Components

Roofing Minimum thickness .55

Attachment system 1

7.70 Olympic Bulb-Tite rivets complete with EPDM washer for weather tight seal

- Shear : 680.915kg

- Tensile : 498.951kg

Attachment system 2 Sikaflex 11FC

A one component polyurethane joint sealant and adhesive.

- Tensile Strength : 0.5MPa

- Tear Strength : 1.5MPa

Testing

Safetor anchors comply with AS/NZS 1891.4:2009 and AS/NZS 5532:2013 standards.

We engaged the services of Telarc registered Material Testing Laboratory and Jason Myburgh of Quality Safety Limited (QSI) to ensure that our products were optimized with both static and dynamic testing.

Material Testing Laboratory static load testing surface anchors.

All tests that were carried out surpassed all regulatory testing standards

We carried out two static tests on both .40 and .55 on a single rib of the roofing material. The load was held for 3 minutes on each test, we used Olympic Bulb-Tite RV6605-0906w rivets as attachments.

The load on both .40 roofing tests was held at 15kN for 3 minutes, the load was then increased to failure. The first test failed at 17kN and the second failed at 16.1kN.

The load on both .55 roofing tests was held at 21kN for 3 minutes, the load was then increased to failure. The first test failed at 23.3kN and the second failed at 22.8kN.

Installation

The installation should only to be carried out by a competent person as set out in the AS/NZS 1891.4:2009 Standards. For added strength the anchor should be sandwiched between the roofing and ridge or apron flashings. We provide a warranty on product performance of the anchor but not the structure or the roof sheeting. It is the responsibility of the installer, building designer, or building owner. If there is any doubt about the structures adequacy, a structural engineer should be consulted.